SUCCESS STORY

With Lean to success: Richard AG optimizes processes and eliminates waste

Establishment of FIFO

and one-piece flow

Fast

responsiveness

Absolute

Planning security

![]()

Brief introduction of the customer

The Swiss company Richard AG, headquartered in Murgenthal, is a leading manufacturer of innovative and flexible solutions in the field of railroad components. With around 130 employees at three locations, the company focuses on the highest quality "Made in Switzerland". In order to sustainably increase efficiency, ergonomics and employee satisfaction, Richard AG launched a lean management initiative in 2021 and has since been consistently converting all assembly areas to BeeWaTec and Kanban solutions.

- The company: Richard AG Murgenthal

- Number of employees: approx. 130

- Project location: Murgenthal, Switzerland

- Status: Existing customer

Summary of the project

Together with BeeWaTec, Richard AG introduced a comprehensive lean management initiative to make assembly processes more efficient, ergonomic and future-proof. The focus was on shorter throughput times, improved material supply at the workplace and the involvement of employees in the design. A lean consultant (Mr. Alpay Acar from the Elite Consulting Group) initially carried out the basics - including value stream analysis, value stream design and identification of waste. BeeWaTec then translated these concepts into reality and developed efficient, flexible and well thought-out workplace systems. With the use of Kanban and BeeWaTec solutions, the throughput time was significantly reduced - a decisive step towards greater efficiency, employee satisfaction and process reliability.

BEFORE

Initial situation and problem definition

- IRIS audits confirmed solid processes, but recommended lean approaches for further optimization (approx. 2018/2019)

- Production was heavily influenced by many parallel assemblies and high inventory levels

- Operational blindness: problems were known, but systematic measures to eliminate them were lacking

- Material supply with gaps: parts were not available and had to be searched for, which led to downtimes

- Long lead times: especially in the main assembly lines.

AFTER

Implementation of lean production with BeeWaTec

After the first IRIS audits, Richard AG received the impetus to introduce lean methods. With the support of lean consultant Mr. Alpay Acar (Elite Consulting Group), the foundations were first laid - including value stream analysis, value stream design and the identification of waste. Based on these concepts, BeeWaTec developed the appropriate workplace and Kanban systems together with the project team. The first assembly lines were quickly converted, resulting in rapid success. A dedicated lean workshop was then created, which can implement adjustments and new solutions directly in-house. In this way, a flexible and sustainable lean production structure was established step by step, which is set to cover all areas by 2027.

Steps on the way to implementation

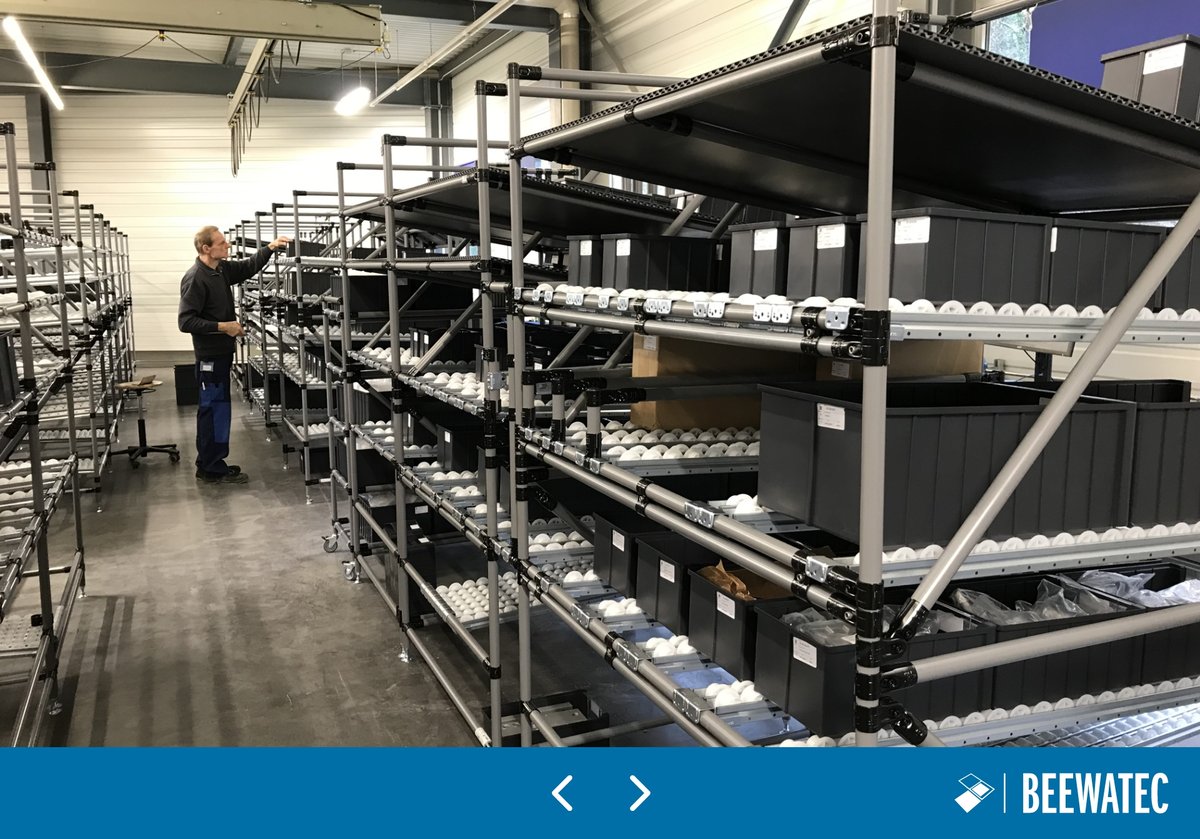

- Introduction of BeeWaTec workstation systems and Kanban racks for efficient material supply.

- Implementation of the externally developed value stream designs in practical, modular workstation solutions.

- Throughput time in main assembly significantly reduced.

- Development of an internal lean workshop with BeeWaTec components (in-house adaptations, rapid implementation, high flexibility).

- Use of the "LEGO principle": Workplace systems can be adapted and expanded at any time.

- New departments always start with value stream mapping and waste detection before BeeWaTec systems are introduced.

- Office Lean is also integrated: Process optimizations beyond production.

- Transition phase until 2027: gradual conversion of all areas to BeeWaTec systems, parallel to the planning of the new building.

Added value and benefits for our customers

- Reduction in throughput times

- Flexible, modular BeeWaTec workstations for quick adjustments.

- Kanban system ensures material supply and minimizes downtimes.

- Improved ergonomics and occupational safety - employees' wishes are taken into account.

- In-house lean workshop enables rapid optimization on site.

- Processes more transparent, waste visible and eliminated.

- New departments (including the new 2027 building) are set up directly in line with lean principles.

Urs Katzenstein, Head of Lean Projects and Quality Management

"

With BeeWaTec, we have made our assembly processes significantly more efficient. The flexible workstation systems and the Kanban concept ensure less downtime, better ergonomics and satisfied employees. Our own lean workshop also allows us to implement improvements directly - a real benefit for our company."

Establishment of FIFO

and one-piece flow

Fast

responsiveness

Absolute

Planning security

BE LEAN, USE BEEWATEC.

Together we will realize your success story.

With BeeWaTec's lean solutions, you can optimize your production processes and sustainably increase efficiency. Our flexible and modular systems adapt to your individual requirements and reduce waste in a targeted manner. The choice is yours: we supply individual components, kits and fully assembled lean solutions.

_Web_01_01.jpg?width=1240&name=Beewatec-3-(37)_Web_01_01.jpg)