Introducing

Introducing

LEAN

You enter the world of lean production to improve processes, material flow, ergonomics and safety.

MODULAR

You receive workplaces the way you want, while focussing on flexibility and future adaptability.

STRONG

You implement high class components to ensure process safety and resilience throughout the years.

IMPROVE ERGONOMICS

Create a safe, comfortable, and efficient workplace that minimizes physical strain, reduces the risk of injuries and promotes overall well-being and productivity.

ELIMINATE WASTE

This is a fundamental principle of lean manufacturing, which streamline the production process and maximize efficiency by minimizing or eliminating waste.

REDUCE COSTS

Improve efficiency and increase profitability by using our energy-saving structures, sustainable products and by creating a seamless workflow.

OPTIMIZE PRODUCTION

Improve and maximize the efficieny and overall performance of the production process, applaying lean manufacturing principles and methods.

Get some inspiration:

Workplace Systems

RACK Systems

CARTS & TROLLEYS

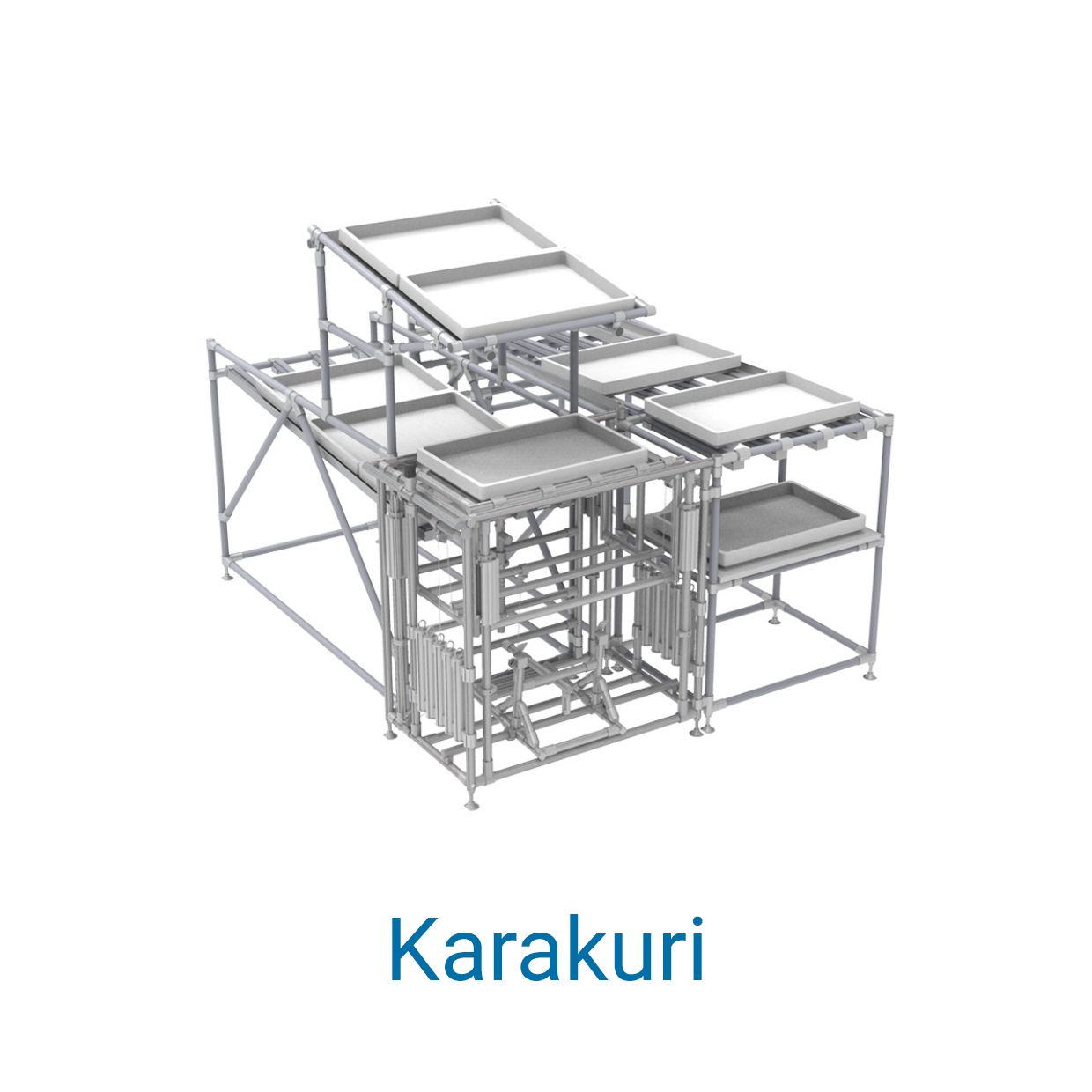

Karakuri

OTHERS

_Web_01_01.jpg?width=1240&height=827&name=Beewatec-3-(37)_Web_01_01.jpg)

For inspiration you can find great projects in our showroom. You can also contact us to share your requirements or start planning your solution by using our 3D-Software.

Material flow

One of BeeWaTec's most important approaches is the implementation of lean principles in our customers' material flow processes. Here, the material flow is optimized in a targeted manner to minimize waste and create a lean, efficient process.

Space optimization and organization

We implement lean production. That is why we take care about your processes and layouts. With lean solutions such as flow racks or workplaces with attached material supply, we help you to organize your production in a smart and simple way.

-jpg.jpeg?width=1240&height=775&name=GROSS%20Kanbanbeh%C3%A4lter%2c%20Kanbanboxe%20(3)-jpg.jpeg)

Production and assembly solutions

At its core, value creation is about mounting, assembly or further processing steps. To help you with that, we design and offer workplace systems that exactly meet your needs, while focusing on ergonomics, safety, health and employee satisfaction.

Ergonomics

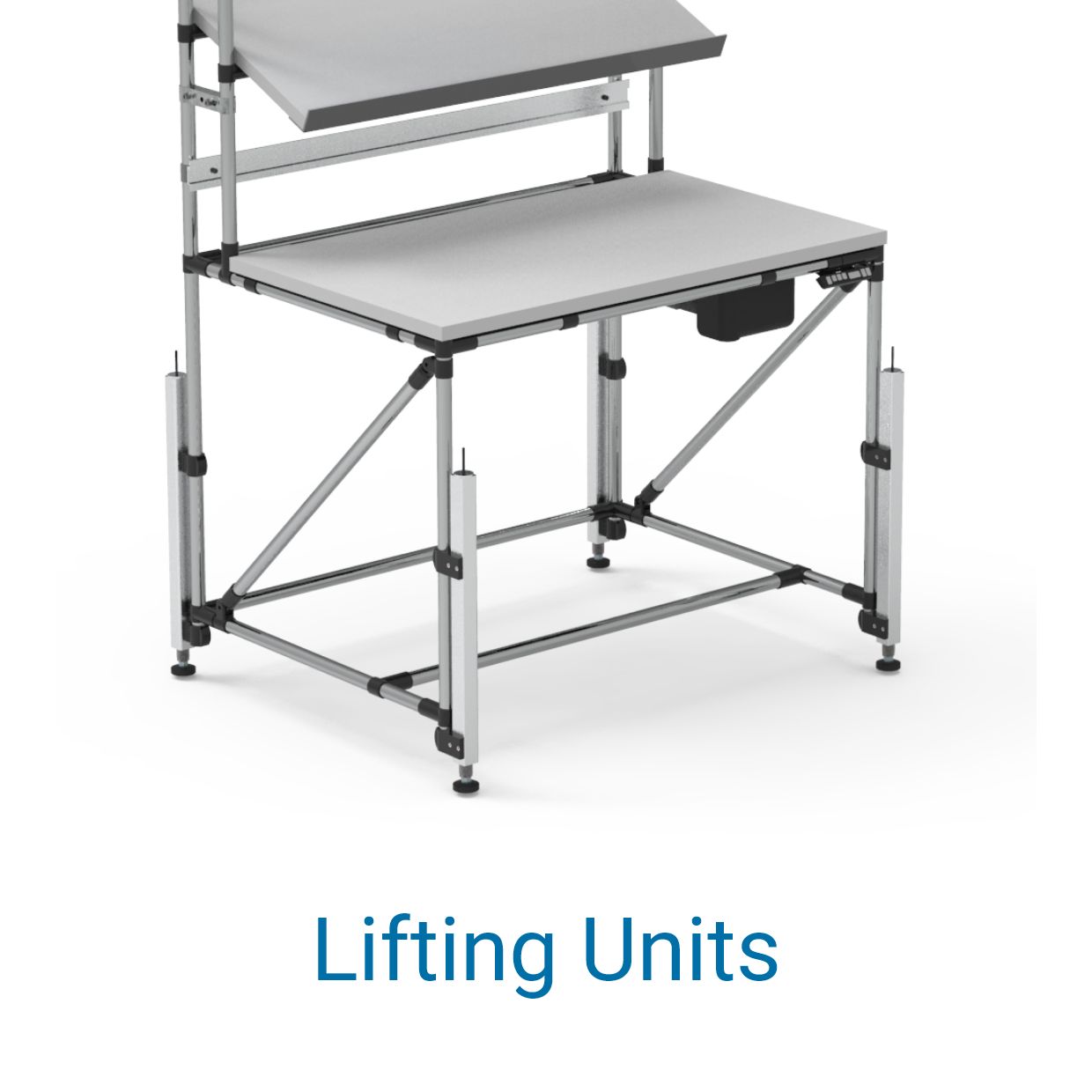

With our modular system, you are able to design ergonomic workplaces and solutions. Height-adjustable workstations, relief for employees through roller tracks or simple Karakuri solutions - they all support healthy work.

_Web_01_01.jpg?width=1240&height=825&name=Beewatec042018-(76)_Web_01_01.jpg)

Safety and ESD

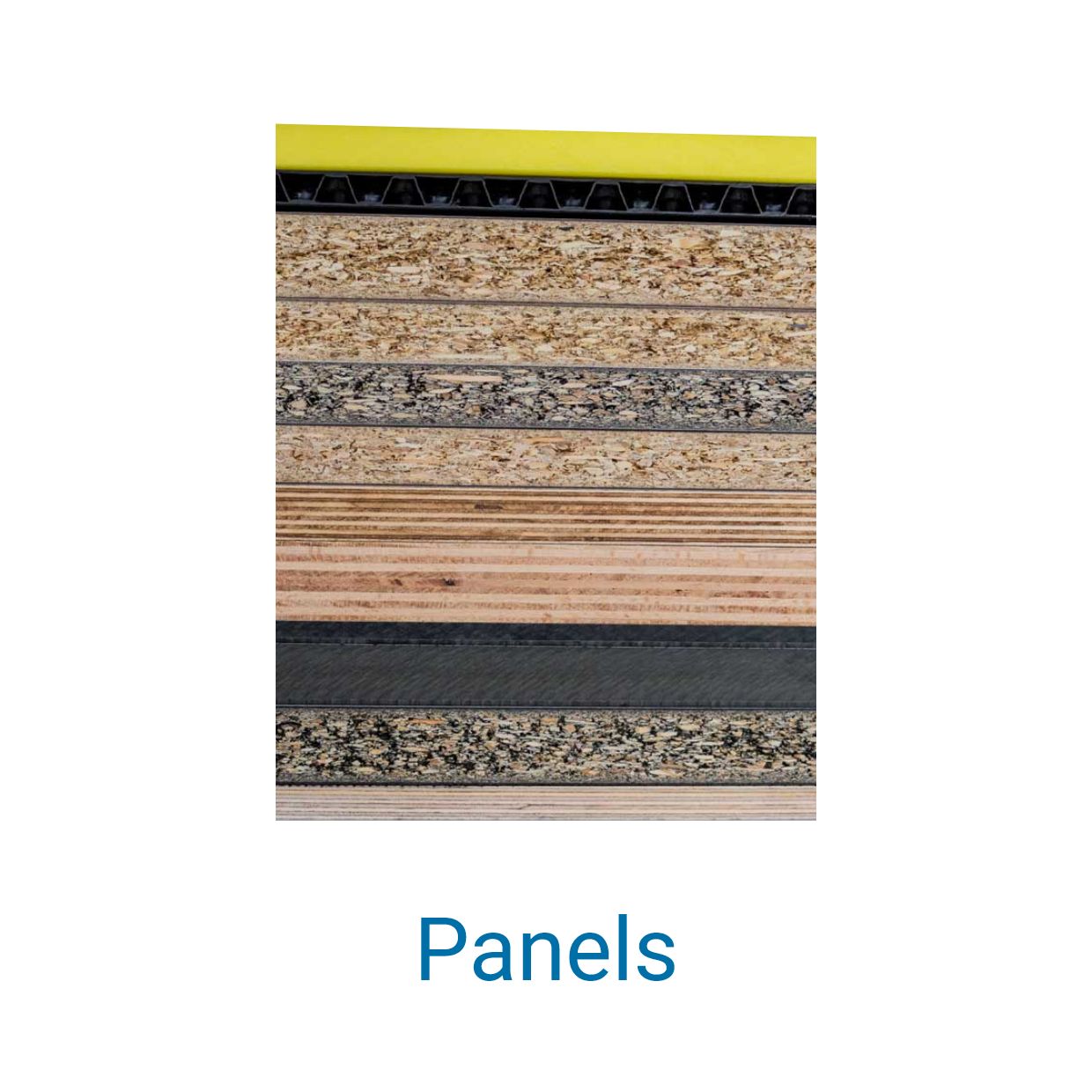

For almost every company, security is a top priority - security in terms of employees, products and processes. Our customized solutions ensure compliance with safety standards such as ESD capability and also guarantee safety for the storage and transport of goods. For this purpose, we have special materials such as our BEESave (= foamed plastic panels) or our new joint protection.

2500+ components

and attachments.

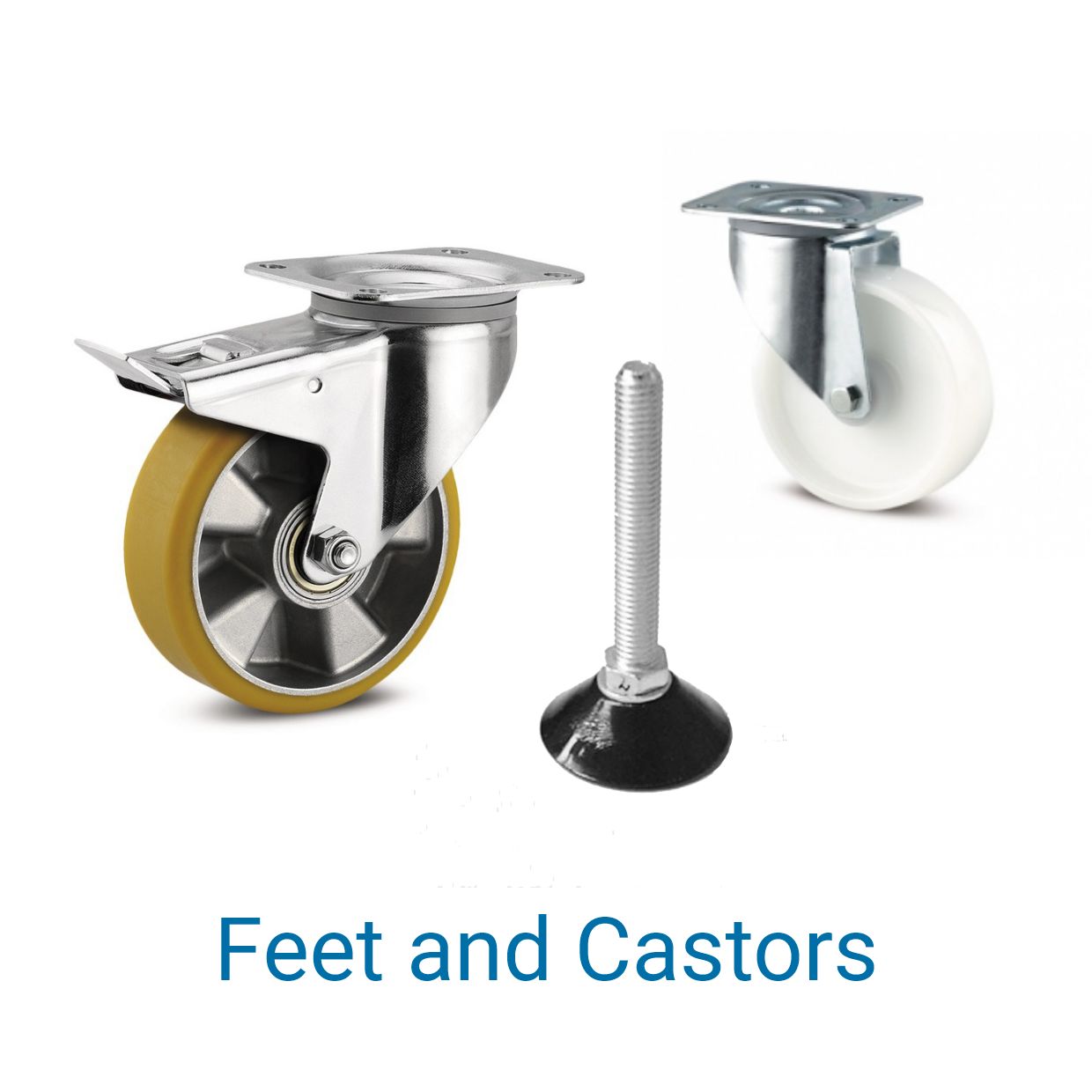

Our lean modular system follows the Toyota principle for maximum efficiency, flexibility and adaptability. We have a huge portfolio to meet your requirements - whether you need round pipes, square pipes, steel, aluminum, ESD - we have it all for you.

You can buy all components separately from us or let us plan your lean solutions.

Automation of transportation tasks,

with unbeatable ROI.

The Genius 2 module from wheel.me transforms racks, trolleys, pallets and more into autonomous mobile robots (AMR). Our round pipes and square profiles made of steel and aluminum offer the perfect way to implement your application. Retrofitting of existing equipment is also possible.

250 kg

load capacity of 4 wheels

<19.000€

price point of 4 wheels

100%

flexibility of dimensions

Safety certification (Level D)

Dynamic obstacle detection

Unlimited flexibility

International group

with on-site support.

With our hands-on mentality and continuous expansion, we created a strong brand in the european market. We act across all borders with serveral warehouses and more than 25 design engineers. Our customers benefit from high availability and short delivery times.

+0

Subsidiaries

+0

Customers

+0

Employees

+0

Million € Revenue (YoY)

We are here for you.

Step 1

A rough sketch helps to showcase problems and ideas and also supports a successful communication.

Step 2

Based on your requirements we create a 3D model and also a technical drawing for free.

Step 3

We start to assemble your solution and bring it into the real world to start a new customer experience.

Select your next step

Please fill out the form below and let us know how you want to get started. We are looking forward to make you lean.

Q&A - Answering

your questions.

We are successful when our customers are successful. To be able to start quickly into a new future we give answers to customer inquiries. You can also contact us directly.

Questions about BeeWaTec

-

Why a lean modular system?

In contrast to conventional operating equipment (e.g. welded constructions), BeeWaTec's Lean modular system offers greater efficiency and flexibility. Thanks to the modular design, ideas can be implemented easily and quickly and adapted at any time should circumstances change in the future.

By combining different pipe systems (e.g. round pipe steel, aluminum square, etc.), all requirements can be implemented cost-effectively - regardless of whether lightweight construction, standard applications, heavy-duty or ESD. -

Why to choose BeeWaTec as a partner?

We have years of experience in the implementation of lean production around europe. We deliver know-how, services and partnership to our customers and make them perform at their very best.

Be Lean, use BeeWaTec.

Talking about our products, we deliver:

- Single components = single parts in standard lengths (e.g. pipes and roller rails), joints and accessories for your project

- Construction kits = construction made by BeeWaTec or by the customer, sawn material incl. construction drawing for independent assembly of your solution

- Assembled solutions = construction made by BeeWaTec or by the customer, solution will be assembled and shipped by BeeWaTec

-

How does a request work?1. Clarify requirements (by phone, online or on site).

2. Design of the ideal solution through BeeWaTec

3. Drawing approval by the customer

4. Preparation of parts list and cutting length optimization

5. Quotation

6. Order

7. Delivery

For orders containing only components, you will receive your offer immediately.

-

Do you have a showroom?

Yes, in fact, we have more:

You can experience the variety, possibilities and stability of our pipe racking system on site in one of our physical showrooms. Simply contact us, we are looking forward to it!

For interested parties and customers who cannot travel to us, we offer a digital showroom with many, successful projects in various product categories ( racking systems, workstations, Karakuri, etc.). We are constantly updating the showroom with new constructions, so it is worthwhile to have a look. -

Do you offer trainings or workshops?

Yes, we offer a Basic Workshop as well as an Advanced Workshop on the subject of "Handling the Pipe Racking System". These give newcomers and advanced users in particular an ideal introduction to the independent planning and construction of operating equipment. Participants learn everything they need to know about construction rules, load-bearing capacities, stability, maintenance and safety.

We also offer training courses for BEEVisio, our design software.

Questions about planning a construction

-

How many kilograms can a BeeWaTec rack hold?

It depends. Due to the modular design of our lean solutions, we like to ask the counter question: How much does it have to hold?

Based on your requirements, we select the appropriate pipes and profiles for loads from 50 kg to approx. 1.5 tons (depending on the profile, the span of the shelf, adjustable feet, rollers, etc.). By using special construction methods (e.g. double pipe technology), reinforced materials or a combination of square and tubular profiles, we can additionally raise the load capacities. -

Does BeeWaTec take over the construction?

Yes, you will receive a technical drawing based on your requirements.

Then we need your drawing approval and you will receive your non-binding offer. The offer is based on the parts list and optimized cutting lengths for long goods (e.g. pipes and roller tracks), which we calculate for you using our free tool BEELopt. -

Can I do the construction by myself?

Of course, you can also plan your lean solutions yourself. Existing customers use our 3D software BEEVisio with CAD catalog of our articles or their internal CAD. For this purpose, we are happy to provide corresponding packages with our articles (e.g. as STEP files).

For the optimization of your cutting you are welcome to use our free tool BEELopt. -

Can BeeWaTec support me in planning the material flow and value stream?

Of course we can provide you some optimization suggestions, tips and "best practices" for your project.

If major restructuring is imminent, or if you need complete material flow or value stream analysis, we are happy to refer you to one of our partners.

Select your next step

Please fill out the form below and let us know how you want to get started. We are looking forward to make you lean.

© BeeWaTec AG, 2026 - All Rights reserved.