use cases for wheel.me

made from the BeeWaTec modular system

Automated transport and efficient processes

Flexible adaptation to any environment

Future-proof and scalable solutions

Trolley Transport

Art.No.: 621074

This trolley structure enables the transportation of materials or boxes in various sizes using a steel frame that is directly mounted on the wheels. The design also ensures dual-sided loading.

Trolley Transport

Art.No.: 621073

This mobile trolley features special designed shelves that hold sensitive parts in place. With a clear plexiglass-enclosed cabinet you benfit from dust-free storage and safe transport across the production site.

Trolley Transport

Art.No.: 621075

This automated milkrun trolley provides ample storage space for transporting sensitive parts, featuring panel coverage and two doors to keep materials especially safe and clean during transit.

Trolley Transport

Art.No.: 621076

A simply constructed transport trolley with twelve textile compartments, designed for transporting components to assembly stations. Particularly suitable for transporting sensitive parts, such as painted parts.

Trolley Transport

Art.No.: 621077

The solution is a material transport trolley with textile compartments that offer sufficient load-bearing capacity and protect the components from scratches and deformation while they are being temporarily stored and transported.

Trolley Transport

Art.No.: 621078

A simply constructed transport trolley with 48 textile compartments, designed for transporting components to assembly stations. Ideal for transporting sensitive parts, such as painted parts.

Trolley Transport

Art.No.: 621079

The ESD trolley with protective grid offers reliable protection for sensitive electronic components against electrostatic discharge. The fencing increases material safety and prevents unauthorized access.

Flying Workstation

Art.No.: 621080

This modular workstation features perforated panels for customizable tool organization, angled storage, integrated drawers, cup holders, a monitor arm and more - creating a floating workspace for efficient and flexible use.

Rack Transport

Art.No.: 621081

This supply rack ensures efficient assembly by providing a continuous supply of seat covers via a hook and rail system. Small items are stored in the upper compartments, while structural core panels protect all materials from dust and dirt.

Rack Transport

Art.No.: 621081

This mobile ESD material rack provides secure storage for sensitive components and features customizable pick-to-light mounting points for improved workflow. The modular, space-saving and vertical design ensures easy adaptation to changing requirements.

Rack Transport

Art.No.: 621083

This slim flow rack supports FIFO storage with five inclined levels, each designed for up to 60 boxes. Offset roller conveyors ensure smooth movement and easier removal of cartons for ergonomic material handling.

Box Transport 3

Art.No.: 601754

wheel.me automates box transport using a shooter system with two transfer stations (source and destination) from the BeeWaTec pipe-racking system, allowing the robot to handle material supply without manual intervention.

Rack Transport

Art.No.: 621081

This supply rack ensures efficient assembly by providing a continuous supply of seat covers via a hook and rail system. Small items are stored in the upper compartments, while structural core panels protect all materials from dust and dirt.

Rack Transport

Art.No.: 621081

This mobile ESD material rack provides secure storage for sensitive components and features customizable pick-to-light mounting points for improved workflow. The modular, space-saving and vertical design ensures easy adaptation to changing requirements.

Rack Transport

Art.No.: 621083

This slim flow rack supports FIFO storage with five inclined levels, each designed for up to 60 boxes. Offset roller conveyors ensure smooth movement and easier removal of cartons for ergonomic material handling.

Rack Transport

Art.No.: 601733

wheel.me transforms the way rack systems and trolleys are transported by turning them into intelligent, mobile units. Whether adapting existing systems or integrating new designs, the robot functions as a self-moving shelf, seamlessly navigating warehouses and production spaces. While load carriers are manually transferred, the system significantly reduces the need for physical effort, optimizes workflows, and enhances flexibility. This leads to smoother operations, better space utilization, and increased efficiency in dynamic environments.

💡 Please consider the manufacturer's specifications for wheel.me for each application at the customer's premises. Please contact us if you have any questions about assembly with the pipe racking system.

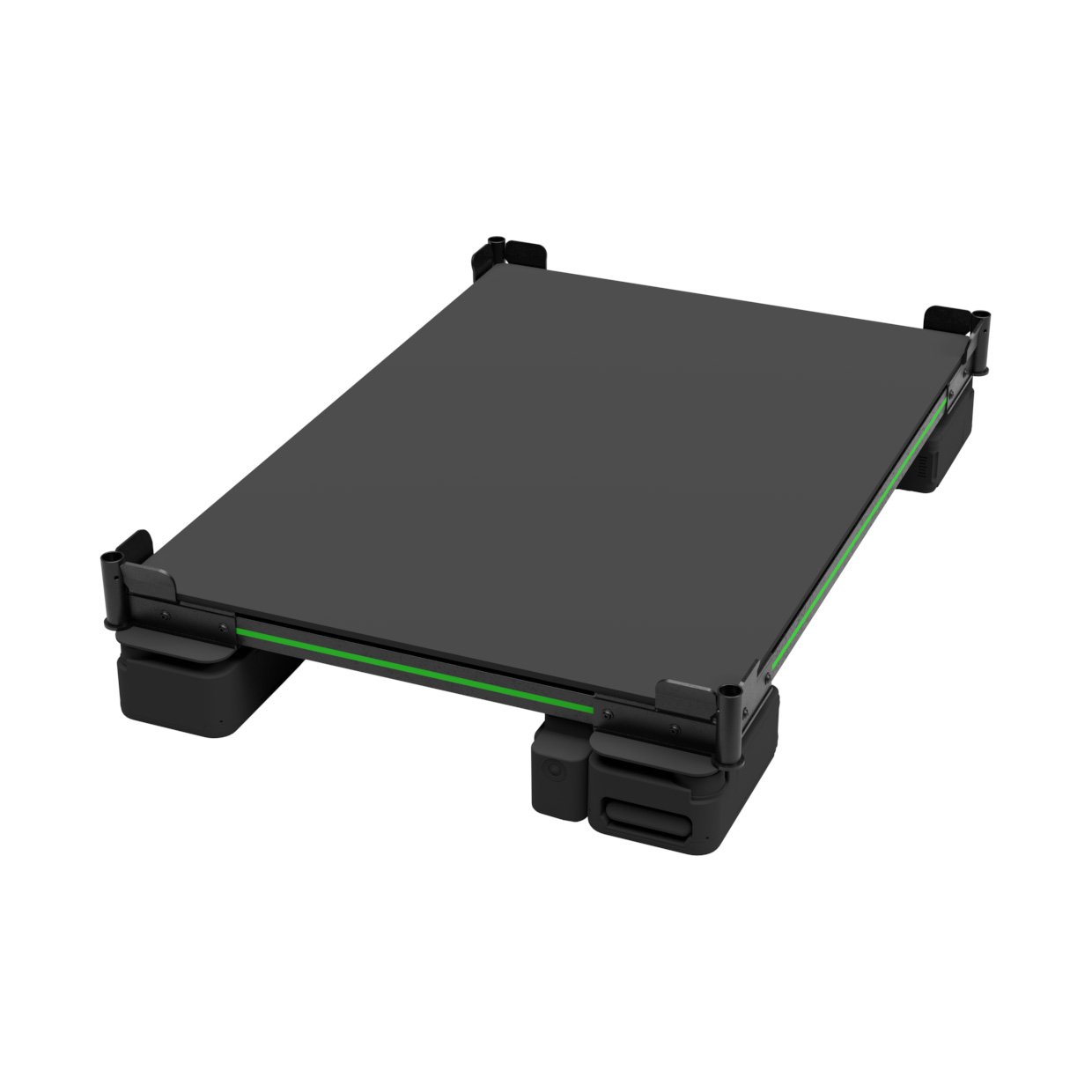

Material Transport

Art.No.: 601742

wheel.me redefines material transportation by integrating a robust steel frame directly mounted on its wheels, turning it into an intelligent, mobile platform. While load carriers are manually transferred, the system minimizes physical strain, streamlines internal logistics, and enhances workflow efficiency. By enabling smooth and flexible movement of pallets, it optimizes space utilization and supports more agile operations in warehouses and production environments.

💡 Please consider the manufacturer's specifications for wheel.me for each application at the customer's premises. Please contact us if you have any questions about assembly with the pipe racking system.

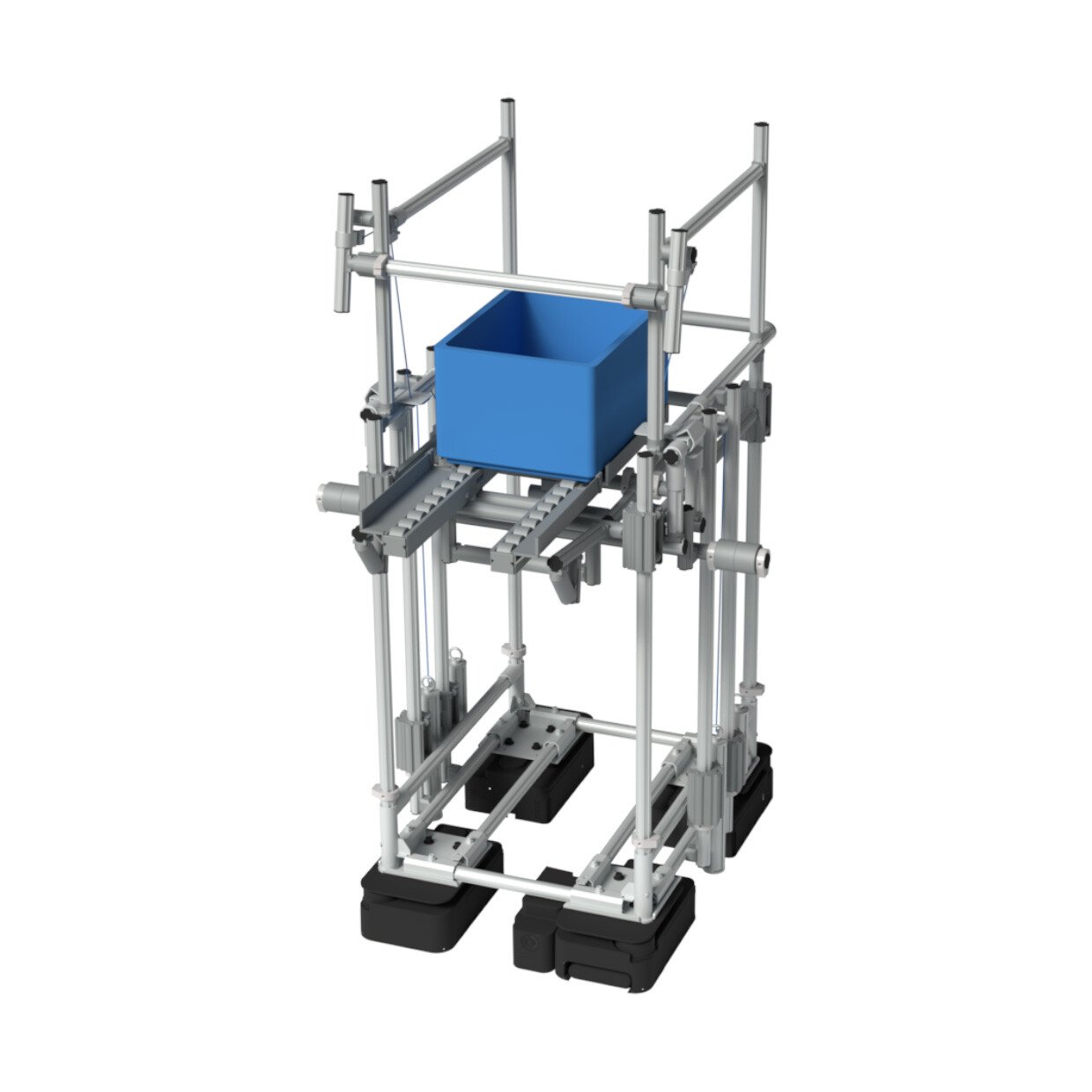

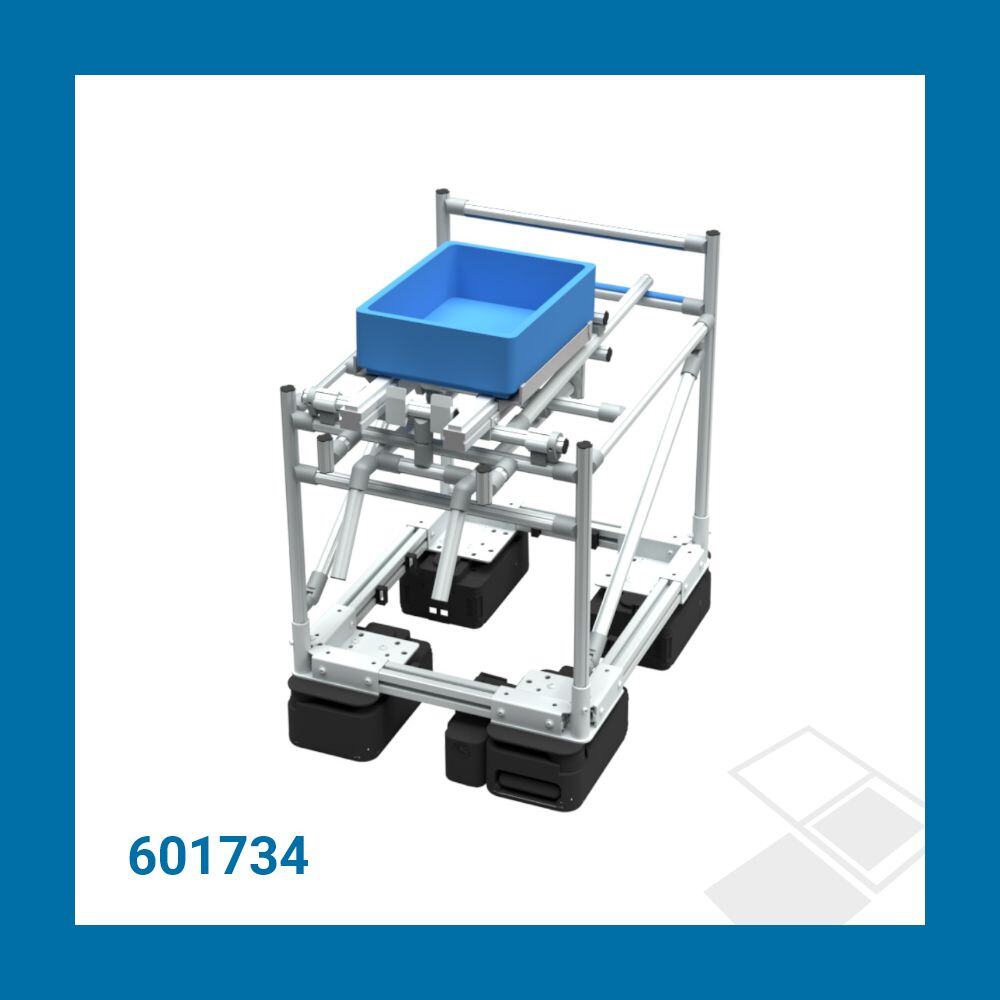

Box Transport No.1

wheel.me revolutionizes material handling by enabling the fully automated transfer of boxes using a shooter system. With two transfer stations — one as the source and one as the destination, built from a BeeWaTec pipe-racking system — the robot seamlessly takes over material supply without any manual intervention. This increases efficiency, ensures a continuous flow of goods, and optimizes internal logistics, making operations more agile and reducing dependency on manual transport.

💡 Please consider the manufacturer's specifications for wheel.me for each application at the customer's premises. Please contact us if you have any questions about assembly with the pipe racking system.

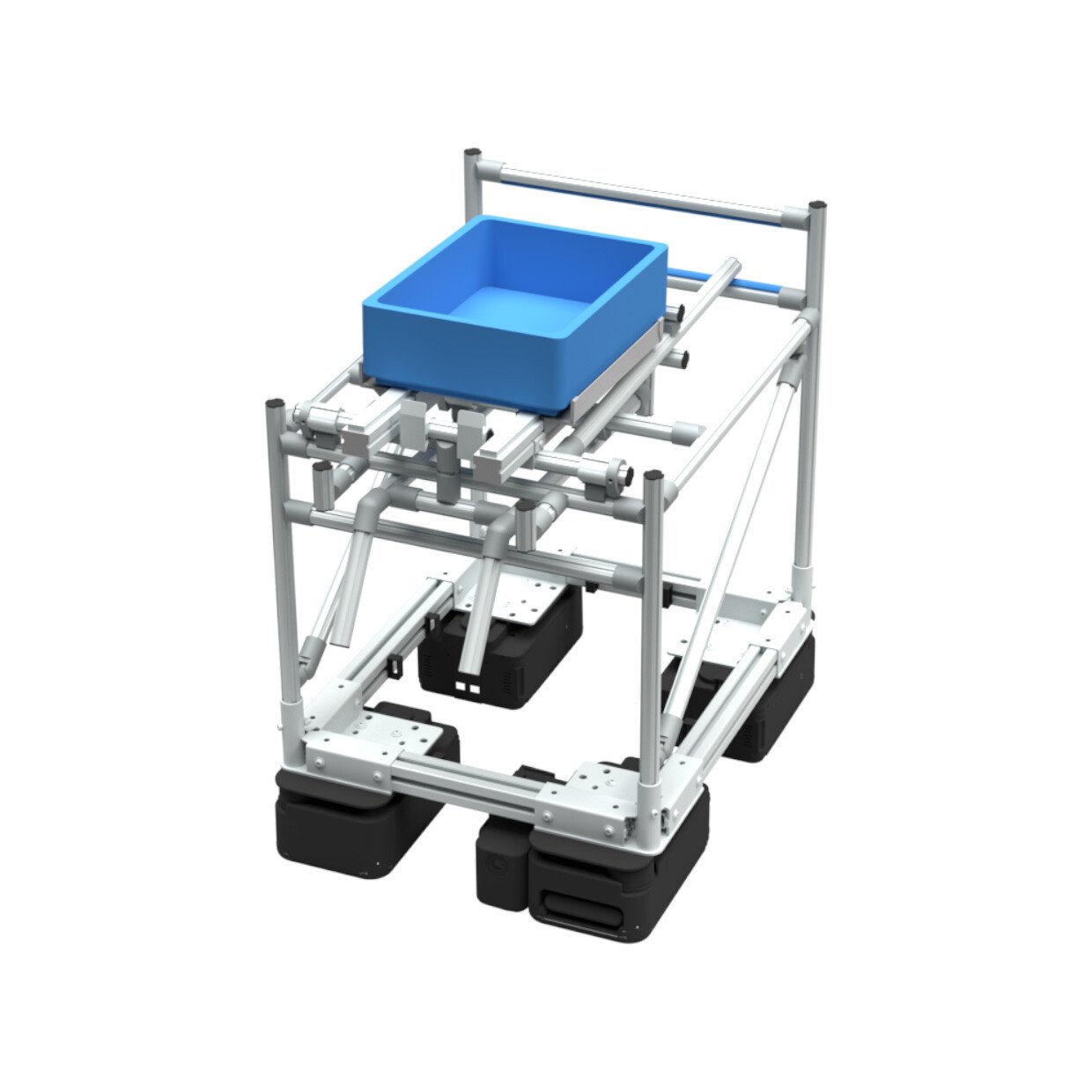

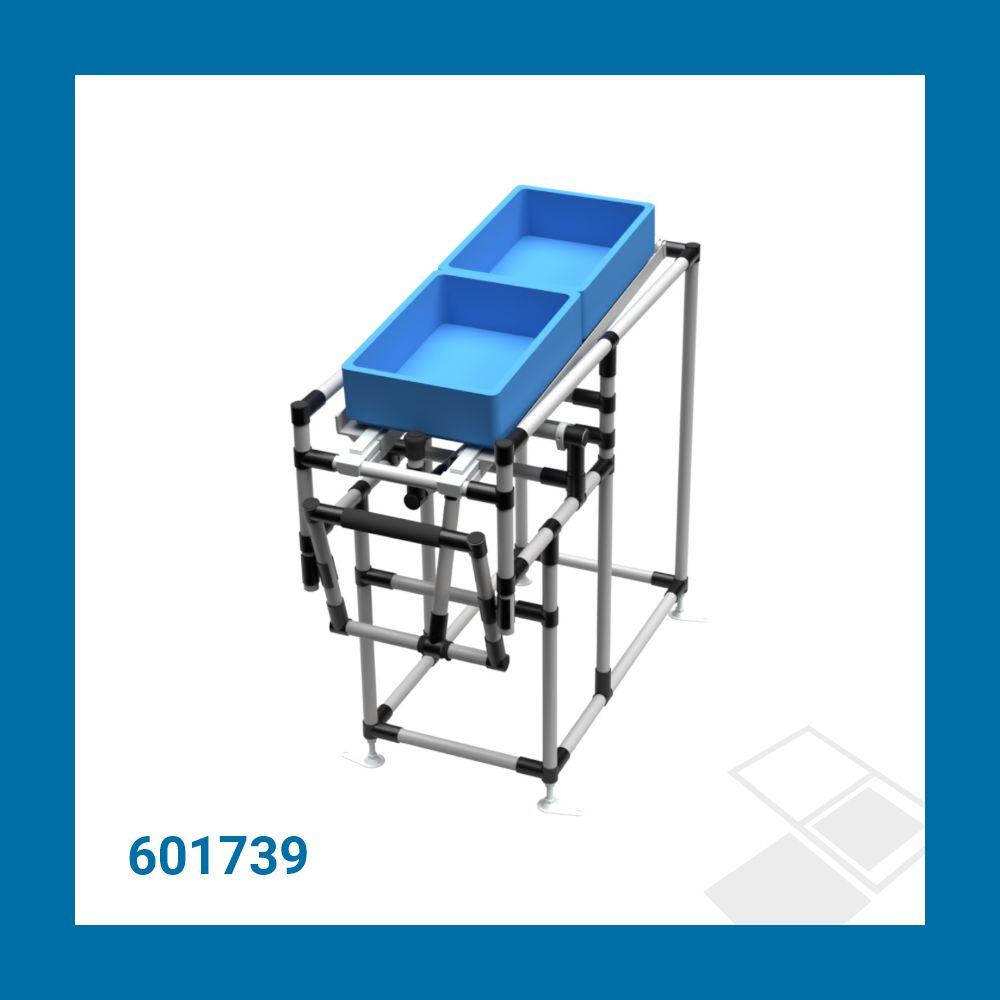

Box Transport No.2

Art.No.: 601738; 601735; 601736; 601737

wheel.me enables fully automated box transport with a height-adjustable sliding carriage and a tilt mechanism for smooth transfer at pick-up and drop-off stations. By dynamically adapting to different station heights, the system ensures seamless material flow without manual intervention. This enhances flexibility, optimizes logistics efficiency, and reduces the need for additional infrastructure, making internal transport more reliable and autonomous.

💡 Please consider the manufacturer's specifications for wheel.me for each application at the customer's premises. Please contact us if you have any questions about assembly with the pipe racking system.

Trolley Transport (Taxi Concept)

Art.No.: 620948

The Taxi Concept combines the autonomous wheel.me platform with the modular BeeWaTec trolley to create a flexible and scalable intralogistics solution. Manually loaded trolleys can be effortlessly placed onto the mobile platform and transported autonomously, streamlining material flows in warehouses and production environments. This low-cost automation approach increases process efficiency, reduces manual handling, and enables fast adaptation to changing logistics needs.

💡 Please consider the manufacturer's specifications for wheel.me for each application at the customer's premises. Please contact us if you have any questions about assembly with the pipe racking system.

Box Transport No.3

Art.No.: 601754; 601755; 601756;

wheel.me is transforming material handling with a fully automated box transfer system powered by an innovative shooter mechanism. Utilizing two transfer stations — one for loading and one for unloading, constructed with a BeeWaTec pipe-racking system — the robot handles material movement autonomously, eliminating the need for manual labor. This solution enhances operational efficiency, maintains a steady flow of goods, and streamlines internal logistics, resulting in greater agility and reduced reliance on manual transport.

💡 Please consider the manufacturer's specifications for wheel.me for each application at the customer's premises. Please contact us if you have any questions about assembly with the pipe racking system.

_Web_01_01.jpg?width=1240&name=Beewatec-3-(37)_Web_01_01.jpg)