Material flow in production and logistics - Definition & all you need to know

The material flow is an important part of every production and logistics. It describes the physical movement of materials, products and goods through...

Modular pipe systems

Attachments

5 min read

![]() Karsten Weiß

:

04.Juli.2023

Karsten Weiß

:

04.Juli.2023

The optimization of internal material flow is an important aspect of process optimization in companies. An optimized material flow can help reduce production costs, shorten lead times, and improve product quality. Both intralogistics and factory planning must work hand in hand with material flow to create a holistic and efficient system and achieve an optimal workflow.

Below are 5 steps for optimizing material flow, along with some tips and an example from the automotive industry.

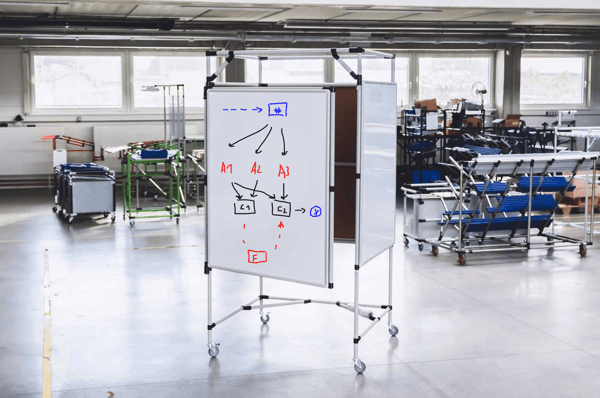

To optimize the material flow, the current process must first be analyzed. In this step, all stations at which material is moved must be identified and documented. Here it is important to involve all employees and departments involved and to document the data carefully. The analysis can be performed using process models or workflow diagrams.

Example of step 1: In an automotive plant, all steps from the procurement of raw materials through production to the delivery of finished vehicles are recorded and visualized. The material flow is tracked from material receipt, material storage, production, assembly and painting to final assembly.

After the material flow has been analyzed, bottlenecks in the process must be identified. Here, it is important to look at the bottlenecks in terms of time and resources and to identify possible causes. Bottlenecks can be caused, for example, by poor warehouse organization, long waiting times at machines or ineffective means of transport.

Creating a map of your value stream is an important first step in identifying potential delays and bottlenecks. Value stream mapping (VSA) allows companies to see the entire flow of data, materials and information related to a product.

By showing the process steps, schedules and lead times required for each element of the value stream, it is easier to identify areas that are causing delays or bottlenecks.

Example of step 2: In the automotive plant, a bottleneck was identified in the delivery of materials to the paint shop because the materials were transported manually to the paint shop, resulting in long waiting times.

After identifying bottlenecks, solutions must be developed to improve the material flow. Several solutions should be considered in order to find an optimal solution. The solutions should be practical to implement and take into account the needs of the company.

Possible solutions can be:

Logistics is an essential part of any business. To ensure successful business operations, the development of a comprehensive logistics strategy that minimizes time and costs is crucial. This strategy should include in-plant and intralogistics solutions for goods transportation and material supply.

This holistic approach to in-plant material flow helps optimize your company's resources while reducing the time and costs associated with material handling.

By incorporating the right strategies into your logistics operations, you can maximize your company's efficiency and save money in the long run. With an effective logistics strategy that minimizes time and costs, you can ensure the long-term success of your business.

An important task in the optimization, planning and design of your production, which is often forgotten, is the flow of information within the processes. This is indispensable for an optimal material flow. Communication between departments must thus be taken into account as well as factory planning or the planning of physical material flows.

Often there are several instances or stakeholders. Accordingly, the requirements are widely scattered and an overall view is usually very complex. In some cases, the topics of planning, implementation and control are also occupied by different people. It is precisely here that a lot of potential is wasted.

Efficient material flow planning thrives on a systematic exchange between all parties involved, with short coordination paths and a high level of decision-making authority. In this way, you benefit sustainably and get optimizations implemented quickly - for maximum flexibility and efficiency.

Digitalization and Industry 4.0 also bring new opportunities on the technical side. Autonomous mobile robots, for example, transport load carriers from A to B 100% autonomously and provide a measurable increase in productivity.

Of course, the topic of automation usually comes with high investment costs. However, in the field of lean production, there are also solutions for low cost automation, completely without electronics, control, cloud, etc. Karakuri applications provide automated flows of goods based on simple mechanical principles.

Example of step 3: To solve the bottleneck in material delivery to the paint shop, the implementation of an automated transport system was considered. A transport robot would automatically transport materials from the material receiving area to the paint shop.

After the solutions have been developed, they must be implemented. Here, it is important that all employees and departments involved are involved and that the implementation is carefully planned. It is also important to consider the impact of the implementation on the entire material flow.

When designing new material and goods flows, material flow systems from BeeWaTec form the ideal basis. Individually designed flow racks, material conveyor sections and workstation systems ensure that the environment adapts to the processes and not the other way around. Greater flexibility, better ergonomics, and lean material supply are further advantages that result from BeeWaTec's modular construction kit.

Example of step 4: The transport robot was integrated into the system and was used on the route from material receiving to the paint shop.

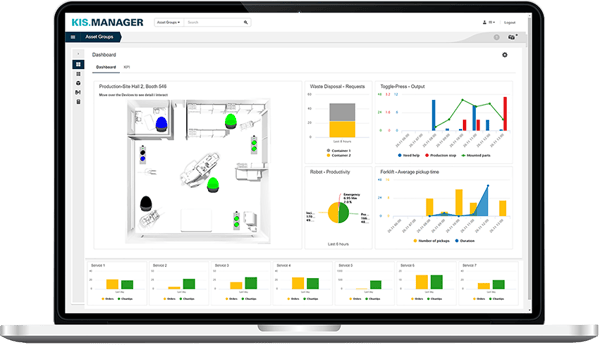

After implementation, the material flow and the newly implemented solutions must be monitored and adjusted as needed. It is important to regularly monitor the performance of the material flow and identify potential problems. Data should be continuously analyzed to identify further improvements.

Data and technology can be used to monitor material flow at every stage of the process. Using KPI (key performance indicators) data analysis, production and logistics teams can easily identify areas for improvement. For example, they can track the movement of materials from one location to another and the speed at which this occurs.

By monitoring the flow of materials in this way, companies can improve their processes and ensure they are using their resources as efficiently as possible. With better data analysis, they can also identify potential problems in their supply chain and make improvements where necessary.

The use of data and technology can help ensure that material flow is monitored and managed efficiently, giving companies more control over their production processes.

Example of step 5: After implementing the transport robot, the performance of the material flow was continuously monitored. It was found that the robot was sometimes stopped due to obstacles in the way. The system was adjusted and sensors were added to detect obstacles early and stop the robot automatically.

Overall, material flow optimization is a continuous process. When companies understand how materials move through a system, they can make changes to their production processes and increase efficiency while reducing resource consumption and costs.

Material flow analysis helps companies identify inefficiencies, reduce waste, improve safety and achieve cost savings - all while improving quality.

BeeWaTec supports its customers in the planning phase as well as in the design and implementation of material flow systems and operating equipment. At the same time, the modular construction kit ensures maximum flexibility in layout planning for a sustainable increase in efficiency.

With our modular system you can build whatever lean solution you need.

Discover your possibilities, exisiting solutions or build your own material flow system with BEEVisio in 3D.

The material flow is an important part of every production and logistics. It describes the physical movement of materials, products and goods through...

In a world where markets are changing rapidly and competition is more intense than ever, organizations are looking for effective methods to remain...

At a time when companies are striving to increase efficiency and cut costs, the concept of lean management has established itself as a highly...