SUCCESS STORY

Introduction of lean production at Swan Analytische Instrumente AG

0%

Reduction in throughput time

0%

Reduction in manufacturing costs

0%

Reduction of process steps

Brief introduction of the customer

The Swiss company Swan Analytische Instrumente AG develops online instruments for analysis in water treatment processes and produces exclusively in Switzerland. In order to maintain its innovative strength and fast delivery times, Swan launched a lean management initiative in 2018 to ensure efficiency and growth.

- Company: Swan Analytical Instruments AG

- Number of employees: approx. 150

- Project location: Hinwil, Switzerland

- Status: Existing customer

Project summary

Swan Analytische Instrumente AG implemented a comprehensive lean management system with BeeWaTec in order to make production processes more efficient. The central objectives were cost reductions, optimized material logistics and shorter throughput times. With the help of lean tools and staff training, flexible, lean structures were created that enabled a significant increase in efficiency, including a 54% reduction in throughput times. BeeWaTec provided support with customized solutions and a Kanban system that improves the flow of materials and saves resources.

BEFORE

Initial situation and problems

- Many production stages led to long throughput times.

- Large number of storage locations on different floors.

- Material was transported to the workbenches and picked up again (“person-to-material” principle).

- Production in large batch sizes due to high set-up costs.

- High dependency on individual workstations and low flexibility during production peaks.

- Inefficient use of storage space and complex material logistics.

AFTER

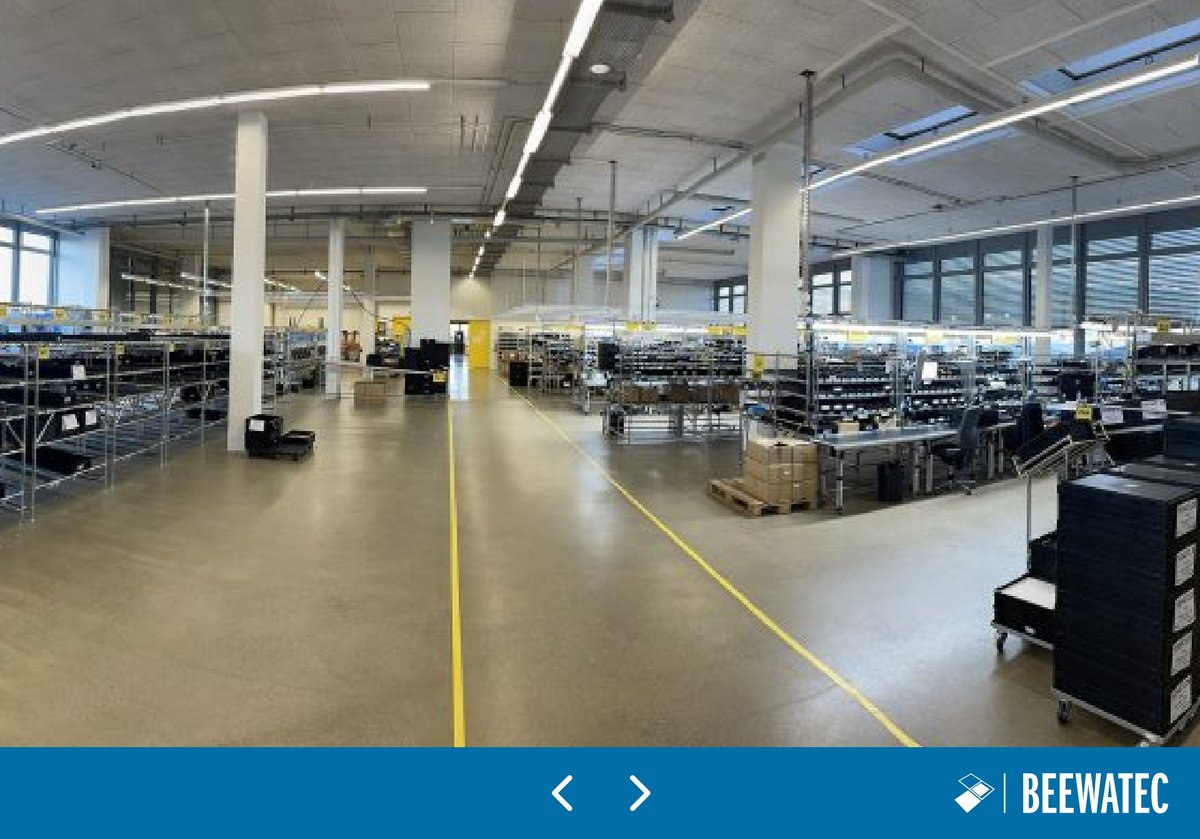

Implementing lean production with BeeWaTec

SWAN worked with BeeWaTec on a comprehensive lean optimization for production and logistics. A new layout, flexible production lines with a supermarket principle and FIFO-controlled material provision created a “breathing” structure that reacts flexibly to fluctuations. Kanban cycles and directly connected test and packaging stations improved the material flow and reduced the process steps by 75%.

Steps on the way to implementation

1. Project start and planning: SWAN and BeeWaTec set up a lean concept to optimize assembly workstations and material logistics and reduce waste.2. Create open space and start conversion: A new building layout was implemented with strict safeguards against delivery interruptions.

3. Redesign material flow: Components are provided in small batch sizes, controlled by FIFO to respond flexibly to production requirements.

4. Testing and packaging facilities: Testing and packaging follow immediately after assembly, reducing process stages by 75% and streamlining the production flow.

Added value and benefits for our customer

- Reduction of production throughput times by 54

- Reduction in manufacturing costs by approx. 8%

- Flexible production structure for rapid adaptation to production peaks

- Ergonomic and more efficient workplace design

- Optimized material supply through Kanban and milk run system

- Reduction in stock levels and savings on provision and disposal costs

- Establishment of a sustainable lean culture for continuous improvement

Alpay Acar, decision-maker and project manager “Supply Chain & Lean Management”

„

BeeWaTec's very wide range of lean production products made it possible to focus on simple and sustainable solutions together. BeeWaTec matched our strategy 1:1 and impressed us with its affordable products with high quality and flexibility!”

0%

Reduction in throughput time

0%

Reduction in manufacturing costs

0%

Reduction of process steps

BE LEAN, USE BEEWATEC.

Together we realize your success story.

With BeeWaTec's lean solutions, you can optimize your production processes and sustainably increase efficiency. Our flexible and modular systems adapt to your individual requirements and reduce waste in a targeted manner. The choice is yours: we supply individual components, kits and fully assembled lean solutions.

_Web_01_01.jpg?width=1240&name=Beewatec-3-(37)_Web_01_01.jpg)