Kaizen - Kaizen principle, Kaizen methods & importance for companies

In a world where markets are changing rapidly and competition is more intense than ever, organizations are looking for effective methods to remain...

Modular pipe systems

Attachments

In a production plant, efficient material supply is essential to keep production running smoothly and cost-efficiently. Poor material supply and logistics can lead to unnecessary delays and downtime in production.

In this article, we'll give you some tips on how to optimize your material supply so that you deliver every customer order on time.

Successful material provisioning starts with early planning of material requirements. To ensure smooth production, you should plan the material requirements for each production unit or operation in advance. In doing so, you should consider not only the quantity required, but also the exact time of material delivery.

At the same time, planning material supply includes the following three aspects:

There are several measures that can help optimize inventory management. Here are some possibilities:

The transport of materials within a company plays an important role in efficient and smooth production. Therefore, it makes sense to optimize material transport as well. Here are some tips on what to look out for in the process:

For optimal provision at the workplace, not only the transport there but also the workplace itself must be adapted. To optimize material provision, various lean solutions such as flow racks or conveyor lines can also be integrated directly at the workplace. In this way, all parts required for assembly or production are automatically provided. This creates a perfect symbiosis of storage and workstation systems for maximum productivity and ergonomics.

Another option is to design flexible workstation systems with shelving levels for open fronted storage bins, for example. Employees benefit from the elimination of individual walkways and are provided with ergonomic gripping paths.

The automation of material supply processes can bring significant time and cost savings. Automated transport equipment such as automated guided vehicles (AGVs) or automated roller conveyors / conveyor belts can speed up material handling and minimize errors. These systems can also reduce the burden on personnel and improve safety.

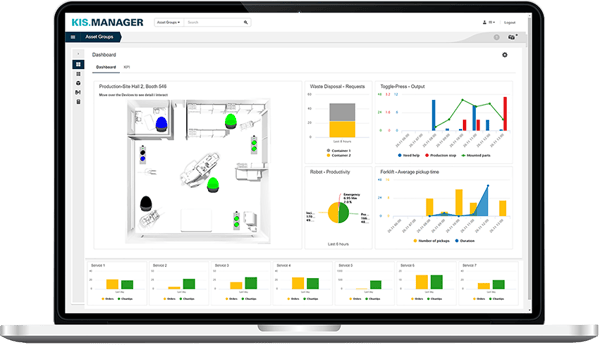

But digital systems can help not only with transportation, but also with managing and recording inventory. Here, for example, information about inventory from production is collected using sensors and monitored in real time. Process chains are thus set in motion automatically and necessary information is shared immediately.

KIS.ME products offer precisely these advantages of process monitoring and control in the cloud. With the help of sensor data, pushbutton boxes and signal lights, you create transparency and gain access regarding the status of your transport orders or waste.

Discover products from KIS.ME >

Efficient material provisioning is essential to ensure smooth production. With the tips mentioned above, you can optimize your material provisioning processes and save time and costs. Taking the above-mentioned components into account, you will reduce unnecessary transport routes and ensure an ideal material flow. It is also important that you regularly review the processes and optimize them if necessary in order to achieve continuous improvement.

With the help of individual flow racks, conveyor sections, transport carts, workstation systems and automation solutions, you can design lean processes and remain flexible for the future. Increasing variant diversity requires flexible concepts in design. Contact us and together we will design your operating equipment for lean and sustainable production.

With our modular system you can build whatever lean solution you need.

Discover your possibilities, exisiting solutions or build your own material flow system with BEEVisio in 3D.

In a world where markets are changing rapidly and competition is more intense than ever, organizations are looking for effective methods to remain...

At a time when companies are striving to increase efficiency and cut costs, the concept of lean management has established itself as a highly...

The material flow is an important part of every production and logistics. It describes the physical movement of materials, products and goods through...